FAST bulletproof helmet NIJ IIIA security protection duty combat helmet

描述

The difference between aramid fiber and high-strength polyethylene

Aramid fiber

Aramid fiber is suitable for high temperature environments, has stronger resistance to sharp puncture, and can face multiple threats. The raw material process is complex and the price is high. It is suitable for scenes that require high temperature resistance, puncture resistance, and long-term reliability.

High strength polyethylene

High-strength polyethylene is 30% lighter than aramid, and is more effective thanaramid fiber in protecting against high-speed fragments. lt has high stability inhumid environments, is mature in production and low in price, and is suitablefor applications that require lightweight, moisture-proof, and cost-sensitive.

Lightweight design

Combination of lightness and protection

We combine material science and engineering design to balance the weight and protection of our helmets, reducing the load on your neck while maintaining protective effectiveness, providing you with comfortable wearing protection.

Modular design

Modularization to meet your needs

Our modular design enables bulletproof helmets to evolve from a single piece of protective equipment to a tactical hub platform through functional decoupling and dynamic reorganization. You can customize the configuration to achieve a precise match between protective performance and mission objectives.

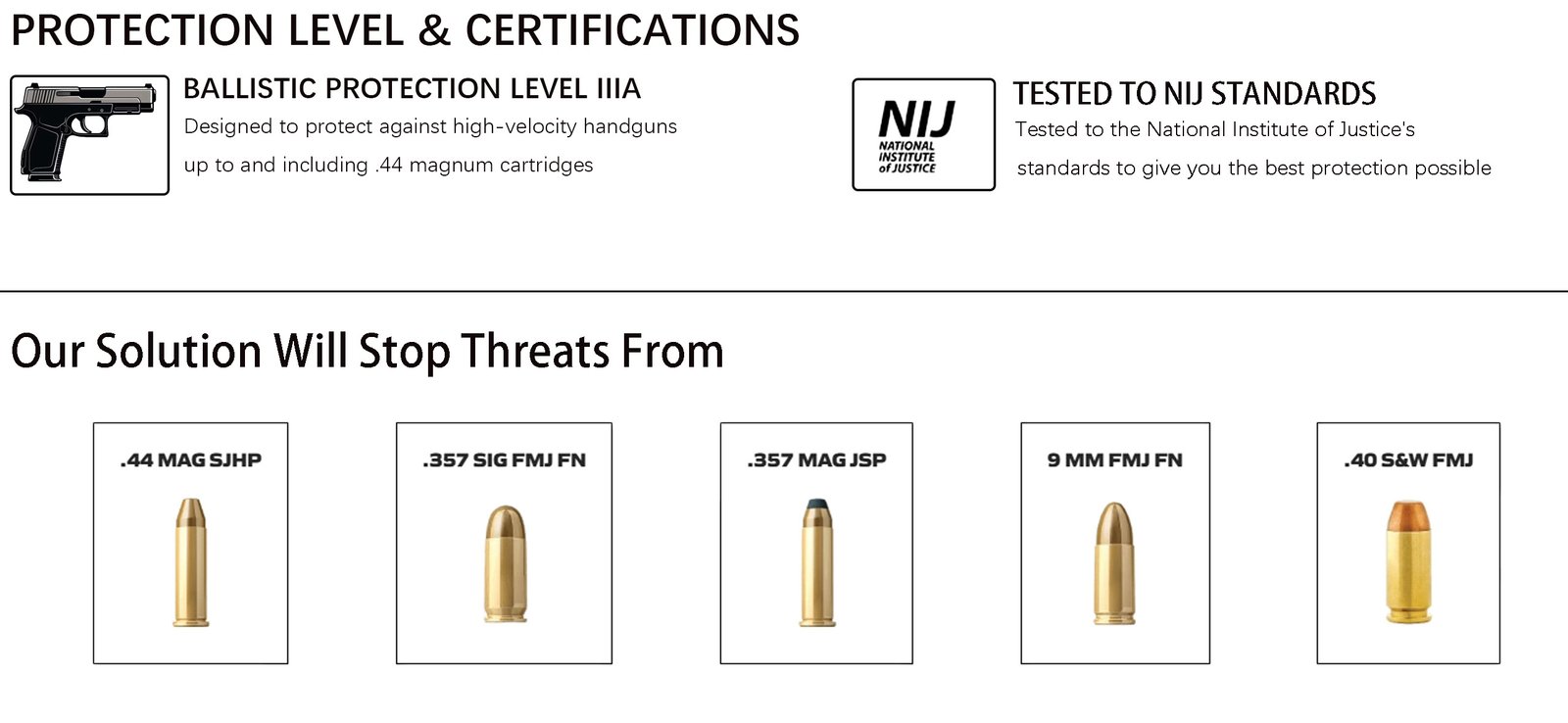

NIJ IIIA level bulletproof vests are the mainstream protective equipment for dealing with handgun threats. With its lightweight, high concealment and diversified design, it is widely used in law enforcement and military fields. Its core advantage is to defend against common handgun bullets, but it should be noted that it has limitations when facing high-speed or armor-piercing ammunition. Higher threat scenarios require upgrading to level III or IV protection.

其他信息

| size | Average size |

|---|---|

| Material | Aramid Fiber, High Strength Polyethylene |

| serial number | 1013 |

成为第一个“FAST bulletproof helmet NIJ IIIA security protection duty combat helmet” 的评价者 取消回复

Related Products

- Quick View

- Buy Now 本产品有多种变体。 可在产品页面上选择这些选项

评价

目前还没有评价